New 7-nanometer chips and a potential insufficient production problem

The demand for chips built with 7-nanometer technology, integrated into the latest PC and mobile products, could lead to insufficient production problems: the success of the new Apple iPhone is also the basis of this dynamic.

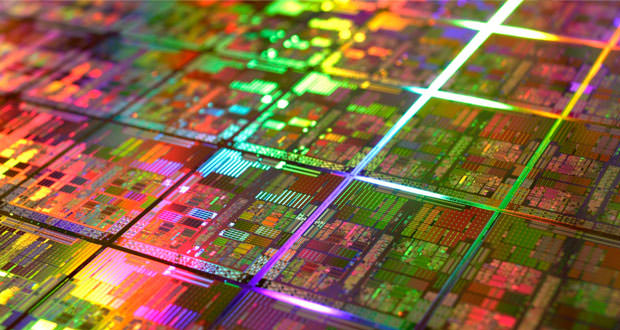

In the market of technology products and gadgets there is a potential problem that faces the horizon. Its name is 7nm and identifies the production technology with which the most recent and powerful chips integrated in the products on the market are built.

This production technology is used for example: by Apple for the SoC implemented in its products of the iPhone and iPad families, both the current generation as the previous one. Or from the AMD Ryzen processors and the video cards of the American company based on Navi architecture, or from all smartphone manufacturers that use one of the latest generation Qualcomm SoC.

At present, there are two companies that produce 7-nanometer chips for third parties: the Taiwanese TSMC and the Korean Samsung. Being a recent and very sophisticated production technology the overall production capacity is not infinite: the producers must allocate what they need balancing the offer by the two manufacturing companies.

In perspective, more and more companies will adopt 7-nanometer production technology for their products: for example: NVIDIA will use TSMC as well as Samsung for its next-generation video chip.

This convergence towards 7-nanometer production technology is potentially such as to create a problem on the horizon: that there are not enough chips for everyone. Some signs have already emerged in recent weeks, and it is now Nikkei Asian Review that indicates how the success of the latest Apple smartphones could generate an unexpected impact on TSMC’s production capacity.

The source highlights how Apple has asked its suppliers for a 10% increase in the production of their iPhone 11, to better respond to the initial demand higher than expected. This implies the need to build about 8 million more smartphones, with obviously as many 7-nanometer SoC that will be integrated into these products.

During the month of September, as indicated by Digitimes, TSMC increased the lead time from the previous 2 months to 6 months. This means that an order for new 7-nanometer chips will be processed within 6 months, requiring manufacturers to make much more accurate strategic planning about the chip volumes they want to be produced by the Taiwanese partner.

An additional demand for A13 Bionic chips from Apple, strong demands for the AMD family from the Ryzen family, traditional volumes and anything but reduced last-generation Qualcomm SoCs for top-of-the-range smartphones and NVIDIA which will pass in the coming months to new GPUs built at 7 nanometers: they are all dynamic in action that could lead to a difficult scenario for producers, able to adequately meet the demand for products from their customers.

The prospects are of a very high market demand, higher than expected and above all such as to saturate the overall production capacity of TSMC. The choice of NVIDIA to have its own GPU produced at TSMC as well as Samsung, presumably conveying some chips and the second others, seems in many ways linked to the desire not to remain tied to a single supplier and in this way to be better balance the demand for new products.

We do not yet know if the overall scenario is such as to create problems for the producers or if the product offer will be such as to meet consumer demand. What is certain is that they all go in the direction of the 7 nanometers for the production of their most recent and powerful chips, and this technology can currently only be managed by two manufacturing companies.

One might think, looking back, that if there is insufficient production capacity, this could generate more direct repercussions on the PC component market GPU and CPU, rather than on the mobile device market. We will monitor the situation over the coming months, looking for signs of difficulty or let us hope, stabilizing the market.